We deliver Granule solutions to plastic goods manufacturing industries within the India.

Our partners and clients value us for the quality of our products.

About

About Us

35

Years experience in Manufacturing

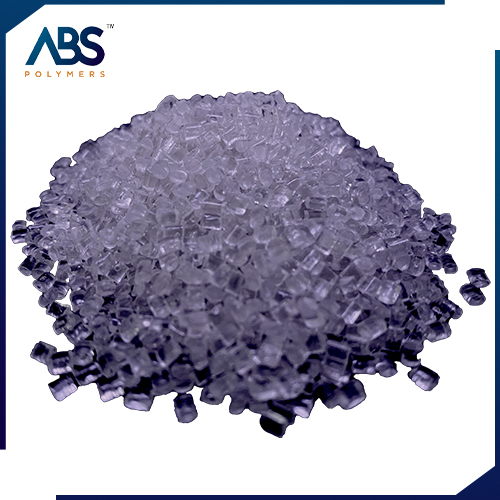

ABS POLYMERS was established in year 1987 at coimbatore Tamilnadu (India). We are engaged in manufacturing and supplying extensive range of granules. Additionally we customize high quality range of plastic granules for a customer specifications.

Production Capacity

We have inbuilt moisture removal and semi-automatic production units, Each machine has capable of 250000 Kgs/per month.

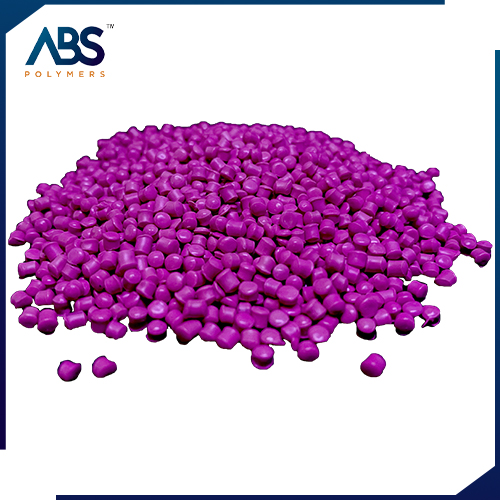

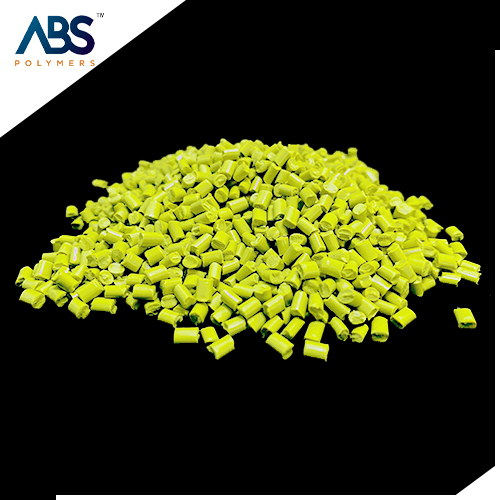

Colouring Solutions

We have advanced machinery for colouring and testing the granules. A unique code will be given to our clients, by approaching with this code, we assure that, the product will de delivered with the same proportion and colour according to the code.

Technology-savvy

ABS Polymer offer special feature in colouring especially fluorescent, phosphorescent articles.

Products

Industrial Products

Let's Deal With Us

Provide You The Highest Quality

Get A Quote

Provide You The Highest Quality

Products That Meets Your Expectation.

Get A Quote

Solutions

Industrial Solutions

Why Us?

Why Choose Us?

Our granules production machinery is well equipped with the latest technology of semi-automatic control pannel with inbuilt moisture removal technology. Each machine has capable of processing 250000 Kgs/per month.

Colouring is an art performed by our well experienced operator as artist. we have the advanced machinery for colouring and testing the granules.

- ABS Plastic Granules

- HIPS Plastic Granules

- PC Plastic Granules

- PC/ABS Plastic Granules

Quality Product

A high level service provider that recommended to any company.

Competitive Price

A high level service provider that recommended to any company.

Quick Delivery

A high level service provider that recommended to any company.

Colouring Solutions

A high level service provider that recommended to any company.

Expert Team

A high level service provider that recommended to any company.

Professional Support

A high level service provider that recommended to any company.

Blogs

Blog News

- 1 Sep, 2025

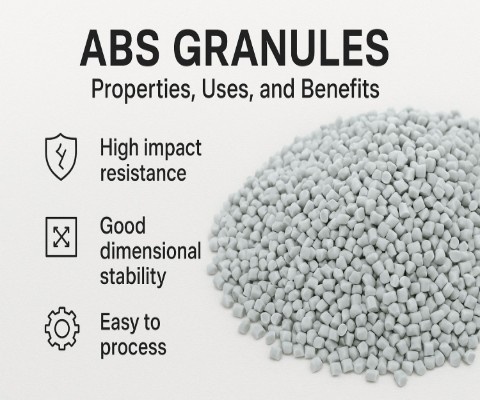

ABS Granules: Properties, Uses, and Benefits

<p data-start="532" data-end="928">ABS (Acrylonitrile Butadiene Styrene) granules are among the most widely used thermoplastic raw materials in the plastics industry. Known for their strength, toughness, and excellent processability, ABS granules serve as the foundation for countless products we use every day. Their unique combination of durability and affordability makes them one of the most versatile plastics in the market.</p><p data-start="930" data-end="1368">ABS granules are valued for their high impact resistance and rigidity, which ensures products can withstand shocks, drops, and heavy usage without cracking. They also offer moderate heat and chemical resistance, making them suitable for industrial applications and consumer products alike. These qualities have made ABS one of the most preferred materials in industries that require long-lasting, reliable, and cost-effective solutions.</p><p data-start="1370" data-end="1879">The applications of ABS granules are incredibly diverse. In the automotive industry, they are used for dashboards, interior trims, and structural components. Electronics manufacturers use ABS for printer housings, monitor casings, and phone covers due to its strength and sleek finish. Consumer goods such as toys, luggage, and kitchen appliances are also commonly made with ABS granules. In addition, the material is popular in plumbing products, fittings, and as a base material for 3D printing filaments.</p><p data-start="1881" data-end="2374">Different grades of ABS granules are available to meet specific requirements. Standard ABS is suitable for general-purpose products, while high-impact ABS is used in applications that demand extra toughness. For industries where fire safety is important, flame-retardant ABS is the preferred choice, and high-heat ABS is used where products must withstand elevated temperatures. ABS can also be supplied in custom colours or with additives like UV stabilisers to increase outdoor durability.</p><p data-start="2376" data-end="2742">Processing ABS granules is simple and cost-efficient. The material is dried to remove moisture, then melted and shaped through methods such as injection moulding or extrusion. After cooling, the products are finished with trimming, painting, or polishing. This ease of processing allows manufacturers to produce products with high precision and consistent quality.</p><p data-start="2744" data-end="3171">Choosing the right ABS granules is critical for manufacturing success. Buyers should look for suppliers that ensure uniform size, consistent colour, and strict quality control. Important factors such as melt flow index, tensile strength, and moisture content should be checked to guarantee performance. High-quality ABS granules not only improve the durability of the final product but also reduce waste and production costs.</p><p>

</p><p data-start="3173" data-end="3721">ABS granules continue to play a vital role in industries that demand lightweight, durable, and versatile materials. Their balance of performance and cost makes them an essential choice for manufacturers worldwide. At <strong data-start="3390" data-end="3406">ABS Polymers</strong>, we provide top-grade ABS granules designed to meet international standards and cater to the diverse needs of automotive, electronics, consumer goods, and industrial applications. With a commitment to quality, consistency, and customer satisfaction, we are your trusted partner for all ABS material requirements.</p>